Sustainable Supply Chain Towards A Conceptual Framework

HLB Corporate Services Ltd

AN INTRODUCTION TO SUSTAINABLE SUPPLY CHAIN

A sustainable supply chain is one that fully integrates ethical and environmentally responsible practices into a competitive and successful model. Ranging from how products are made, to the type of packaging used for shipments, to reducing carbon offsets during last-mile delivery, a sustainable supply chain takes into account the effort(s) made in planning and executing policies, processes, materials, and technologies across all logistics systems and operations that are geared towards making a more positive impact environmentally, socially, and economically.

In order for businesses and organisations to achieve sustainable supply chains, there are 3 key components that are of paramount significance. Green, transparent, and circular supply chains are all components of a modern sustainable supply chain.

Green Supply Chain: Green supply chains use ethical and environmentally sound practices at every stage, with the goal of reducing air, water, and waste pollution. This can be achieved by successfully integrating environmentally responsible principles and benchmarks into supply chain management. This includes product design, materials sourcing, manufacturing, logistics, and end-of-life product management.

Transparent Supply Chain: Supply chain transparency, in essence, means that a business or an organisation knows exactly what is happening at every stage of its supply chain, and communicates clearly stated as well as factually backed information about its supply chain operations internally and externally. The ability and willingness of a business to openly disclose information about the provenance of goods, labour and end-to-end supply chain practices allows it to gain greater visibility in order to manage risks more effectively.

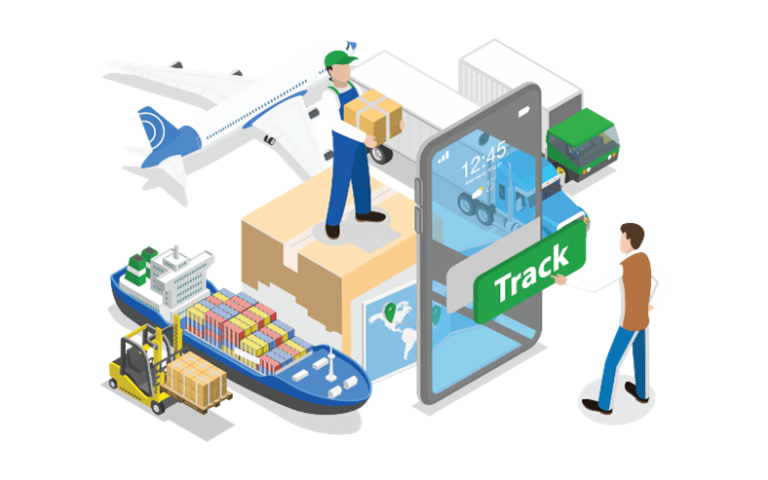

Circular Supply Chain: The circular supply chain is a model that encourages manufacturers and sellers of products to take discarded materials and remake them for resale. The win-win nature of this model is growing in popularity, and, according to a 2020 Gartner survey, 70% of supply chain leaders plan to invest in the circular economy. Some of the modern technologies that support these initiatives include the use of recycled plastics in 3D printing and the ability for advanced analytics to map out the most efficient logistics journeys for returning products into the supply chain loop.

Circular Supply Chain: The circular supply chain is a model that encourages manufacturers and sellers of products to take discarded materials and remake them for resale. The win-win nature of this model is growing in popularity, and, according to a 2020 Gartner survey, 70% of supply chain leaders plan to invest in the circular economy. Some of the modern technologies that support these initiatives include the use of recycled plastics in 3D printing and the ability for advanced analytics to map out the most efficient logistics journeys for returning products into the supply chain loop.

SUSTAINABLE SUPPLY CHAIN MANAGEMENT (SSCM)

Supply chain management is the practice of coordinating sourcing, production, inventory management and transportation among all the participants in a supply chain to maximize efficiency and customer satisfaction.

Including the element of ‘sustainability’ into supply chain management involves the proper management of related environmental, social, and economic impacts in constructing and maintaining effective and efficient global supply chains.

SSCM encourages governance practices at all levels of the lifecycles of goods and services that reduce waste, ensure long-term maintainability and economic value of environmental & social well-being of all stakeholders’ interest in the creation and delivery of products and services.

Although it is a very difficult task to bring into the decision process of the rights and needs of all interested stakeholders in the marketplace, it is to the long-term benefit of the properly managed supply chain relationships and corporate sustainability initiatives that ultimately promote broad-based sustainable development objectives for the benefit of people, plant, and profits (i.e., triple bottom-line).

THE IMPORTANCE OF STARTING AT THE SOURCE

For many companies, sustainability is no longer just something to monitor, but integral to the foundation of their supply chain. Integrating environmental data into procurement tools and processes, using environmental metrics alongside cost and quality stats are important processes that are used to evaluate suppliers at the very source. Many businesses and organisations have even started to provide sustainability training to their own procurement managers and suppliers to help the cause.

As far as the literature is concerned, Forrester Research has developed a framework for integrating sustainability deep into organisations’ supply chain, with a focus on four areas:

- Procurement: Most companies start sustainability programs by looking at energy and water procurement, and by procuring sustainable materials to use in their products.

- Operations: Organisations also need to delve into operational processes or steps across the supply chain that could be more efficient and reduce resource usage.

- Retirement: The reduction of excess waste and obsolete items by designing products for upcycling and reuse will also help companies towards their objective of implementing a sustainable supply chain.

- Data and communication: Measuring the effectiveness of initiatives in the first three areas, and strengthening any related efforts, by communicating them to customers, supply chain partners and other stakeholders will promote transparency among all stakeholders.

WHAT ARE THE KEY CHALLENGES?

Cost is the primary impediment to sustainable supply chains, with smaller companies finding it particularly difficult to afford the upfront costs of making a supply chain more sustainable. However, an investment in something like compact packaging, for example, can lead to a reduction in the size and number of shipments, a lower environmental footprint and cost savings over time.

Other companies find that there simply aren’t sustainable options for components, or that they’ve inherited supply chains from acquisitions that are difficult to shift towards sustainable practices because of complexity or organizational structure. These challenges can be overcome, however, 20% of respondents in a survey reported that customers simply weren’t interested. This makes it difficult for some companies to justify the added expense or effort.

THE FUTURE OF GLOBAL SUPPLY CHAINS & SUSTAINABLE OPERATIONS

Innovation has and will drive supply chain sustainability in the years to come. Two trends that will keep momentum going in this area are the circular economy and data-driven supply chains.

The goal of a circular economy is to design pollution and waste out of products and systems like supply chains. In this system, products are built to have a light environmental footprint, last longer and be easily disassembled and remade or transformed for reuse.

In data-driven supply chains, companies leverage cloud-based supply chain execution systems that provide detailed analytics and may even pull data from equipment sensors and other Internet of Things (IoT) devices. This gives businesses deeper visibility into their operations, and they can then find, implement and monitor strategies to become more sustainable.